Wall Bracing

A full range of Dunnings manufactured bracing used to provide bracing strength during wall frame construction

Applications

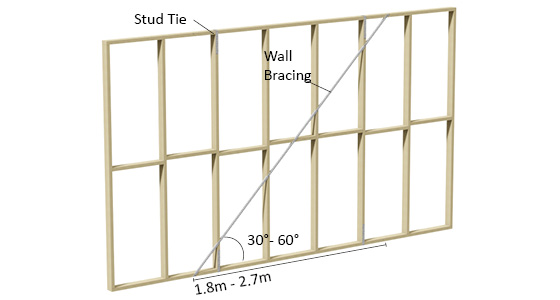

- Position the Wall Bracing as specified by the frame drawings or code requirement.

- Mark the saw cut position using the Wall Bracing edge as guide, making sure that the angle between top plate and Wall Bracing is approximately 45° (but no less than 30° and no greater than 60°).

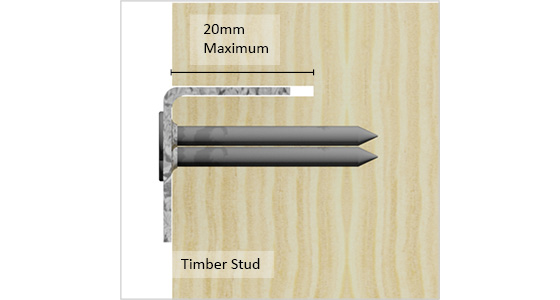

- Cut the marked studs and plates to a depth of 18mm (no deeper than 20mm).

- Place the unpunched leg of the Wall Bracing into the saw cut, with the punched leg facing towards the bottom plate.

- Trim the Wall Bracing to the required length.

- Fix the Wall Bracing to each stud and each plate using 2/30 x 2.8mm Dunnings’ nails.

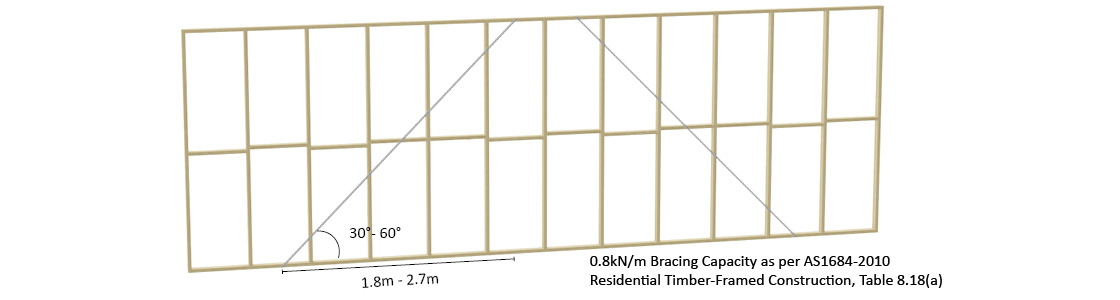

Typical Use

1.5kN/m Bracing Capacity as per AS1684-2010 Residential Timber-Framed Construction, Table 8.18(c)

Notching

The maximum depth of a notch or saw-cut shall NOT exceed 20mm.

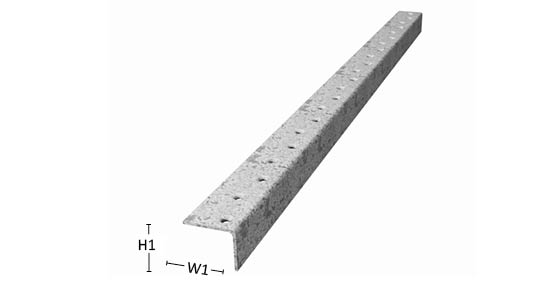

Product Specification |

Product Code |

|---|---|

| DES Wall Brace Galvanised (nominal) 20 x 18 x 1.2mm x 3.6m Length |

BDB1.2X3.6 |

| DES Wall Brace Galvanised (nominal) 20 x 18 x 1.2mm x 4.2m Length |

BDB1.2X4.2 |

| DES Wall Brace Galvanised (nominal) 20 x 18 x 1.2mm x 4.8m Length |

BDB1.2X4.8 |

Material Specification | |

|---|---|

| Thickness: | 1.2mm |

| Material: | G300-Z275 |

Nails | |

|---|---|

| BN 30 x 2.8mm Galvanised Timber Connector nails |